Installation Guide

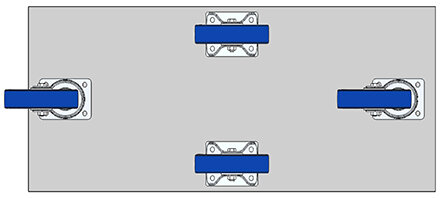

The trolley will work best on a flat floor and 4 wheels must be in contact with the floor. So:

- Use caster of the same Series.

- If you use casters from 2 different Series, Then you must ensure the all the casters have the same installation height. If not, you can add a thicker/ slimmer base plate or washers to make them even.

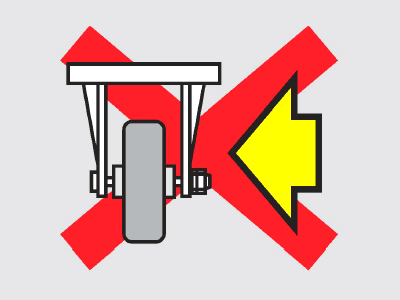

Pay attention to the swivel radius of the swivel casters. If those limit lines of the swivel radius touch each other, every time the vehicle changes direction, it will be stuck or hissed when pulling or pushing.

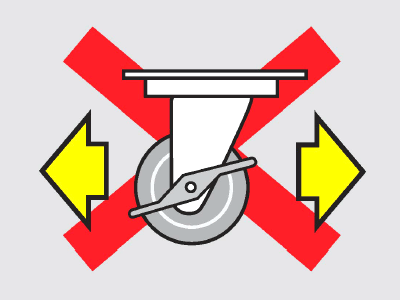

Rigid casters must be installed parallel to each other.

Use the right type of bolts and lugs, fasten the caster to the platform before using.

Installation plans

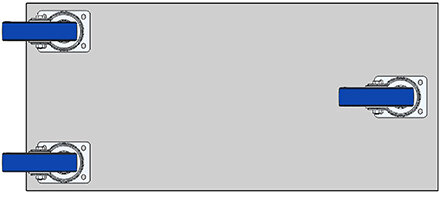

Household: 3 Swivel Casters

Light duty and flexible. Can easy to change direction.

However, you will find it quite difficult to drive straight and may overturn if the road is steep

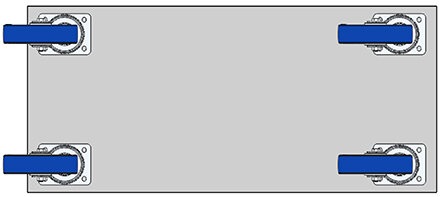

Narrow places: 4 Swivel Casters

The trolley can move in all directions including horizontally or diagonally, suitable for tight areas with many corners.

In a spacious place, it will be a bit difficult for you to drive the trolley straight.

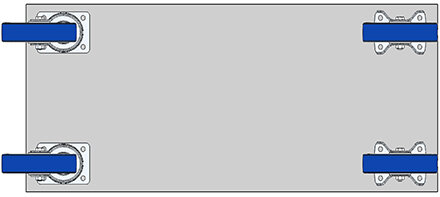

Common: 2 Swivel and 2 Rigid Casters

The most common installation plan. Used to transport goods on wide roads and have to go far.

Rigid casters have directional effect, preventing loss of steering.

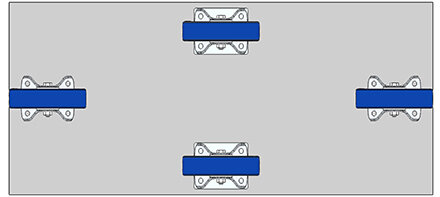

Economical: 4 Rigid Casters

The two middle casters (or a set of axle mounted wheels) are mounted higher than the front and rear wheels.

This trolley is easy to go straight and can still change direction when needed. But it require 2 people operating to prevent the vehicle from rolling over.

Trailing trolley: Diamond shape with 2 Swivel and 2 Rigid Casters

Designed to be suitable for towing. The trolley can steer and steer straight quite easily.

Trolley can roll over, so springs with shock absorbers should be used. The 2 Swivel Casters in the middle can be changed to 2 wheels with a through shaft combination.

Combo 6: 4 Swivel and 2 Rigid Casters

Also designed to be used as a trailer, requiring a long or heavy trolley.

2 wheels with a through shaft combination can be used to replace the 2 Rigid caster in the middle.

User manual

1. Movement Speed

In room temperature (20 – 30°C) and flat floor conditions, accelerate the trolley gradually, then maintain:

- ≤ 2km/h for wheel with diameter ≤ 80mm.

- ≤ 4km/h for wheel with diameter greater than 80mm.

Pay attention, observe and drive the trolley to avoid obstacles, bad surfaces due to impact and vibration will cause caster to wear quickly or may be damaged.

Do not let casters and trollies operate continuously for a long time. Because friction during operation will increase the temperature at the contacts and joints, accelerating wear and aging.

2. Regular cleaning and maintenance

Depending on how using frequently, you can periodically maintain per 1 month, 3 months, 6 months or 1 year. The jobs are:

- Remove foreign obstacles such as fiber, hair, rag, etc. which are caught by the tread and shaft of the wheel. Then dust or vacuum dirt.

- Wipe dry water, steam clinging to the floor, steel bracket to prevent rust and corrosion.

- Check the bearing ball of the swivel head. Remove dirt and re-grease.

- Check bearings of the wheel whether replacement and maintenance is required.

- Check the brake whether it it functioning OK or not.

- Examine the wheel surface. If you find any signs of tearing, check the floor for hole, sharp obstacles. If it is broken, see if there is the impact of gasoline or chemicals.

- Re-fasten the nuts.

3. Follow the Guidelines for Safe Use

Do not overload the load indicated on the Catalog and guidance of the sales staff.

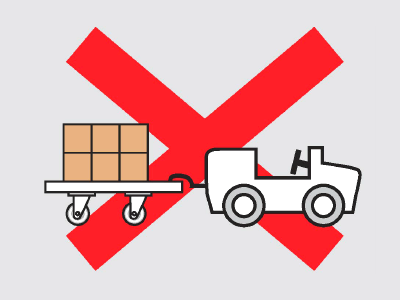

Do not hook a tractor trolleys, trams to ensure slow moving, accelerated slowly and do not exceed the movement speed of 4-6 km/h. Create a safe distance for people around by letting the vehicles running on separate lanes

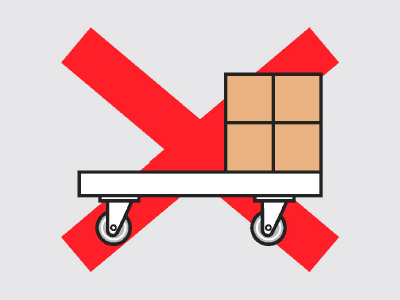

Line up evenly based on the platform. Much favor of one side may result a rollover.

Use the trolley system intended purpose. No climbing, playing on the platform.

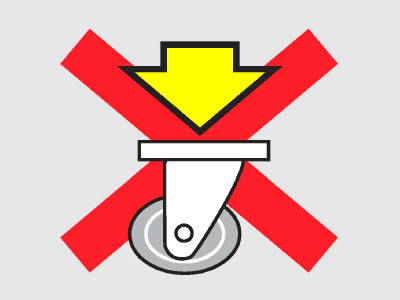

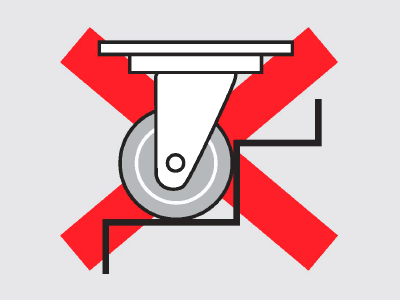

When operating the trolley with wheels fixed installation, you avoid horizontal forces impact on this type of wheel. If it’s long-term impact or makes wheels turn, twist causing misalignment shorten the life of the product.

Check the wheel in locked or not before pushing.

Do not push the car on the stairs, wheels are easy to be damaged by the impact of natural forces: vibration, inertial force when the cart "fall" from the top down to grade levels below.

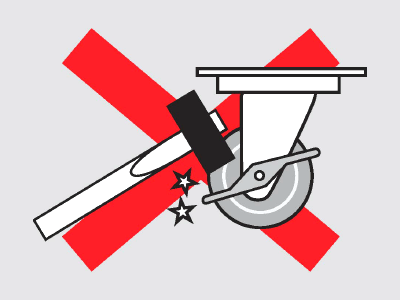

The design of the lock is required normal force to operate. Absolutely not apply grand force or it may damage the lock and parts.

The cart should operate on even floor surfaces.

Firmly lock the cart when stopping or parking on ramp. Also need to put additional warning signs for people around the car may be gone downhill.

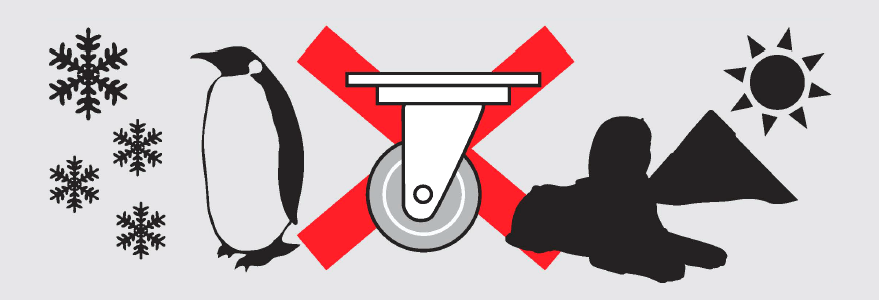

Notes the impact of weather conditions to normal operation of the cart

- When unused put the trolley under roof to avoid sun and rain.

- If the temperature is too cold or too hot, a dedicated heat-resistant caster must be used.

- In sea area which is wet and salty, it is recommended to use caster with a stainless steel bracket of SUS 304 and PA wheel.